앞선 기술력과 고객 최우선의 가치아래 제품들을 개발하고 있습니다.

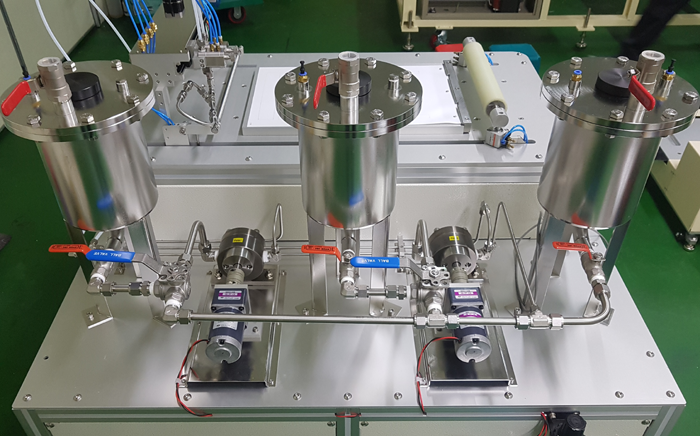

•생산 개발용 Laminating & Dispensing Bar Coater

제품개요

본 장비는 인쇄 sheet를 Plate 위에 올린 후 이액형 Dispenser를 이용하여 용액을

토출 후 Bar Coating을 한후 Roller를 이용하여 라미네이팅을 진행 하는 장비이다.

제품특징

• 디지털 제어방식으로 user 원하는 정밀한 제어가 가능하다.

• 원하는 코팅속도 및 거리를 설정 하여 동일한 조건의 반복 재현이 가능하다.

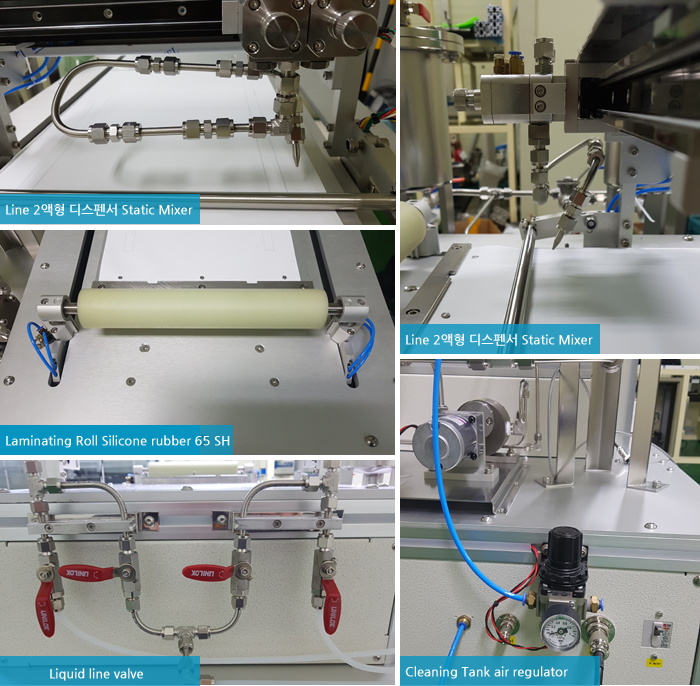

• Line 2액형 디스펜서 Static Mixer로 주제와 경화제를 자연교반하여 토출한다.

• 속도조절을 다양하게 하여 Coating 및 Laminating 할 수 있다.

• 특수한 설계로 진동이 거의없다.

• 다양한 악세사리로 옵션적용이 가능하다.

제품사양

-

•Control Display :

Digital Display

•Speed : Standard Type : Max 5~80mm/sec (USER 사양제작)

•Material : SUS, AL(경질 표면처리), Steel(Powder Coating)

•Coating Type : Dispensing Bar Coating (Wire-bar Rolling Coating)

•Stage Plate : AL Polishing 정밀가공 후 하드아노다이징

•Plate Size : 320mm(W) × 482mm(L)

•Dispenser Type : Line 2액형 디스펜서 Static Mixer

•Dispensing Speed : 10~60 mm/sec

•Liquid Tank : 경화제 Tank , 주제 Tank , Cleaning Tank 각 1ea

•Tank capacity : 각 5ℓ

•Liquid Pump : 기어 펌프

•Laminating Roll : ø50 x L300mm Silicone rubber 65 SH

•Power : 220V AC 50/60H