앞선 기술력과 고객 최우선의 가치아래 제품들을 개발하고 있습니다.

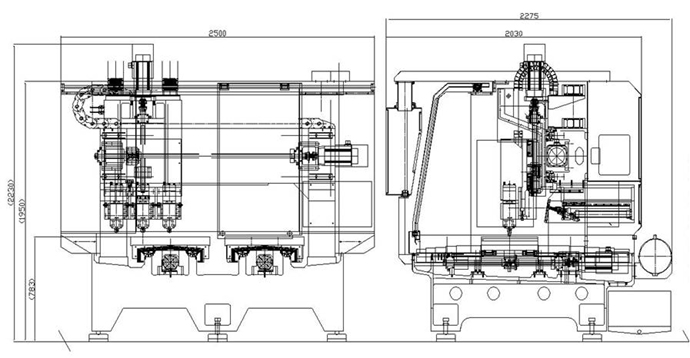

Simultaneous 3 axes HT8050D-3MA 스마트폰 강화 Glass 최첨단 가공장비 입니다.

|

•

CNC Controller & Servomoto

|

•

기계표준사양

▶ 3축 2테이블 방식(테이블 프로그램에 의한 자동 전환)

▶ 30,000~40,000RPM의 고주파 핀들 기본(20mm이내 전착 휠 및 엔드밀,FACE CUTTER등 사용가능)

▶ FEED UNIT 부분 정밀급 LM가이드 적용 및 볼스크류 적용

▶ 유선형 MPG설치 및 작업등 기본설치

▶ 글라스 및 아크릴작업에 최적화된 CNC시스템 적용(범용 적용 가능)

▶ CNC 자체 프로그램 입력 가능 및 CAM 데이터 입출력 시스템 기본 장착

(232통신포트 및 USB포트설치)

▶ 알파캠,마스터캠 등 CAM프로그램 100%호환

• OPTIONAL

▶ 주축 스핀들 속도(30,000 /40,000)

▶ CNC 콘트롤러 선택(FARGOR, FANUC, TURBOTECH)

▶ 절삭유, AIR 선택 및 동시 부착가능

▶ 자동지그 및 일반 지그 선택

▶ 일반테이블 및 진공 테이블 설치선택(자동지그는 일반 테이블에만 장착가능)

▶ 진공타입 선택(이젝터,진공탱크, 무진공)

▶ COLLET 및 COLLET CHUCK 타입선택 및 사양선택(HSK 25/32, ISO, SK...)

•

STANDARD & OPTIONAL

- STANDARD

▶ Infinitely variable feed movement on X, Y, Z axis with FAGOR servomotor

▶ High precision ball screw on 4 axes

▶ Ground slide way on longitudinal and vertical axis

▶ Telescopic complete chip cover on bed for the cross movement

▶ Bed, column, saddle and head in Meehanite cast iron

▶ Centralized controls on pendant electrical control panel

▶ Flood coolant system with tank and 6 bar coolant pump

▶ Axis with FAGOR digital servomotor

▶ Automatic power function

▶ Air blow

▶ LM guide

▶ Flood coolant system

▶ Work light

▶ Portable hand wheel

▶ Swivelling operator panel

▶ X, Y, Z axis linear scale

▶ Centralized lubrication system

▶ Oil cooler

- OPTIONAL

▶ Work piece measurer

▶ FANUC/FAGOR/HEIDENHAIN controller

|

•

DAUL WORK TABLE

|

|

•

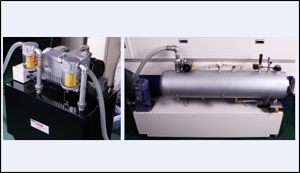

VACUUM BUFFER SYSTEM

|